Brief introduction

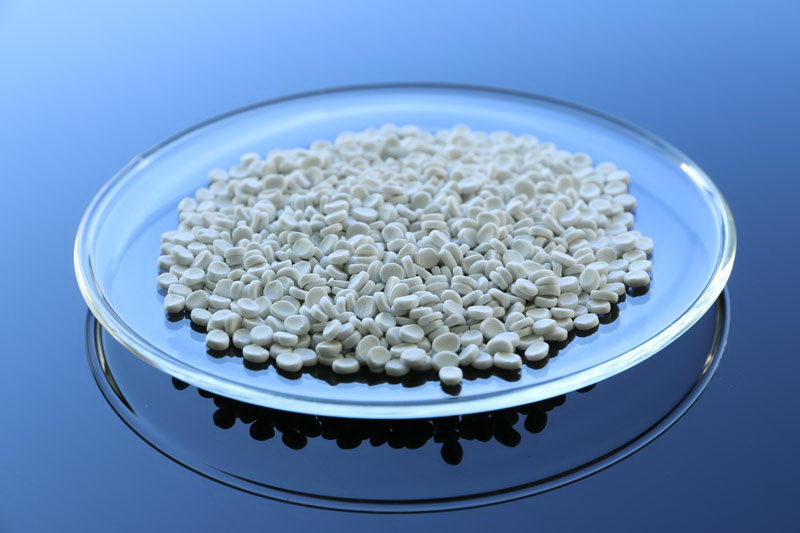

Calcium powder filling masterbatch products with PE / PP carriers, and to 800 head - 3000 Head of calcium carbonate particles, silane coupling agent and other special processing aids, the rigorous processing and. Having excellent physical properties (properties of plastics), dispersion, stability, does not affect the precision of the machine screw. Can be widely used in all kinds of PE, PP, PS, ABS and other plastic products, such as PE plastic bag, injection molding, extrusion can incineration treatment of environmental protection plastic products such as plastic products, especially. The amount of up to 80%, greatly reducing the cost of the finished product. And do not affect the quality of products and gloss, acid and alkali resistance, high temperature resistant, non-toxic and tasteless.

Physical characteristics

| Item | Test Method | Values | Unit |

|---|---|---|---|

| Density | GB1033-86 | 1.4-1.82 | g/cm3 |

| Melt FlowIndex | GB3682-89 | 2-20 | g/10min |

| Moisture | Q/HJYH-2002 | < 0.01 | % |

| Colour | - | White |

Products have been detected by SGS.

Product features

The product is used for filling calcium carbonate filler masterbatch, suitable for all kinds of products of the production of polyethylene, polypropylene.

- Good dispersion, good compatibility with polyethylene and polypropylene, even if the high proportion of filling is not falling off, can still get a good finish.

- Low calorific value, burning oil dripping, no black smoke, no two pollution, and no damage to the incinerator;

- Printing, good gloss;

- Breathable film products.

- White opacity reduces the amount of white pigment used;

- Working environment is improved and it is easy to measure automatically;

- Save raw material storage space;

- Reduce the cost.

- High Whiteness: This product is white granular, flexible preparation products produced in various colors.

Applicable scope

- Suitable for blown film, salivation, hollow plate, tube, hollow blow molding, injection molding, drawing and other process, and according to customer requirements, design and processing of special material.

- PE, PP, blown film, vest bag, shopping bag, garbage bag, cast film, breathable film, Straw, etc. and printing plastic bags.

The proportion of application

- The application of the proportion of TC series filling masterbatch

- The film PE 5-50% vest bags, garbage bags, woven bags

- PP drawing 5-35%

- Packaged with PP 30-50%

- LDPE 20-60% injection molding plastic tray, plastic pots, switch box, plastic toys

- HDPE 10-30%

- PP 20-50% plastic pipe, sheet, mat sheet

- LDPE 10-30% hollow blow molding hollow molding barrel, bottle

- HDPE 5-30%

- PP 20-30%

Packing

Well closed, plastic woven bag lined with PE bag (with moisture-proof) packing: 25kg/ bag

Product storage and storage

Calcium powder filling masterbatch products stored in dry, ventilated place, storage period of 8 months, avoid the sun and rain.