The main component of transparent filler masterbatch

Transparent filler masterbatch with mixture of ultrafine powder and a variety of compounds, with fine quality anhydrous sodium sulfate or talcum powder as the main raw material of plastic modifier, through the optimized combination of carrier, coupling agent, compatibilizer, with excellent compatibility and dispersibility. Use ratio of plastic raw material can improve the plastic toughness, dimensional stability, is a kind of high performance, low cost, friendly environment functional masterbatch.

Transparent filler masterbatch physical index

- Melt index: 1-15g/10min

- Moisture: <0.001g

- Density:

- (anhydrous sodium sulfate) transparent masterbatch 1.6-1.8g/cm3

- (talc) transparent filler masterbatch 1.6-1.85g/cm3

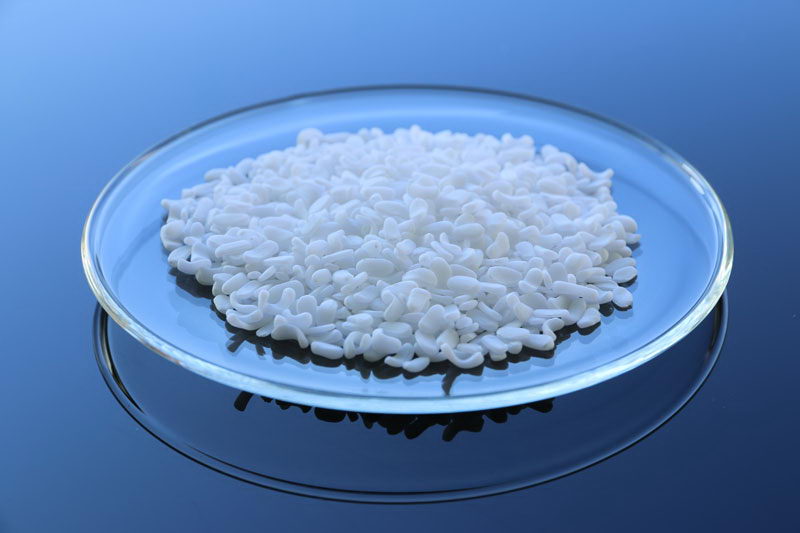

- Appearance: white particles (talc powder grade white gray particles), good plastic performance, feel fine.

- Transparent filler masterbatch products have been detected by SGS.

Transparent filler masterbatch product features

- Adopts the unique advanced powder surface modification process, the preparation of high mesh (1250 mesh - 5000 mesh) powder and polymer blend was prepared by inorganic organic nanocomposite materials. The filler masterbatch and polyethylene (PE, PP) resin has excellent compatibility and finished surface gloss.

- Can use ordinary equipment processing, does not affect the product in the processing of melt flow, processing technology need not change, the mechanical equipment wear.

- The elimination of bright little influence on product performance, high light transmittance, smooth, better printing performance.

- Non toxic and non stimulating, delicate, good plastic, uniform size, does not affect the mechanical properties, more excellent than the ordinary additive.

- The product is resistant to acid and alkali, resistant to organic solvents, excellent electrical insulation properties.

Transparent filler masterbatch products application

Suitable for film blowing, blow molding, injection molding, sheet, pipe, all kinds of PP, PE plastic products.

Transparent filler masterbatch proportion

The film was added to 5-50%

Blowing bottle to add the amount of 15-30%

Sheet, plate, pipe, injection molding can be added 10-30%

Transparent filler masterbatch product packaging

Outer packing adopts compound woven bag or coated paper woven bag, inner packaging compound packaging bag, net weight 25kg.

Transparent filler masterbatch products storage and storage

Products stored in dry, ventilated place, storage period of 6 months, avoid the sun and rain.